NOTE: This article appeared in Issue 315 of Circuit Cellar, back in October 2016. I’ve posted it here for your reading pleasure as well. References to previous articles are for Circuit Cellar Issues, as this was originally written for the print publication. This version differs slightly from the print version – this is my own ‘author copy’ version before the Circuit Cellar editing.

Back in December 2015, I discussed how I solder BGA devices (such as FPGAs) using a low-cost reflow oven. This article will discuss the design of the FPGA board itself, which you could then assemble using the tips in my previous article.

I’ll assume you have a rough idea of what external parts you need, as they will be highly dependant on what you are trying to accomplish with your design. In addition to design-specific information, there are a few standards external requirements such as programming interface, communications, and power. This article will briefly cover some of these external requirements, but the concentration of this article is how to physically lay-out the FPGA board at a reasonable cost.

Some of the topics I covered previously too – for example in my June 2015 article I discussed the use of a generic USB microcontroller as a FPGA interface chip, which is very useful if you need to shuffle data to/from the FPGA.

So let’s assume you have a (mostly) complete schematic, and are wondering how to make this a reality. Let’s start with setting a target goal in terms of board requirements.

PCB Specifications

Assuming this design will be either a prototype run or possibly a small production run, it makes sense to design your PCB with specific requirements in mind to keep costs reasonable. The two PCB specifications you are most commonly told are the minimum “trace/space” (that is, minimum width of a trace, and minimum spacing between copper features), and the minimum drill size.

As I mentioned in my previous article, I’m often using an overseas PCB fab at 3pcb.com, although many other options are worth trying. They offer a variety of trace/space and drill size options, so I’ll target a 5 mil space/trace with 0.2 mm drill. This is a fairly “standard” technology option, so shouldn’t be a problem when moving towards a small production run (i.e., Qty 100-200).

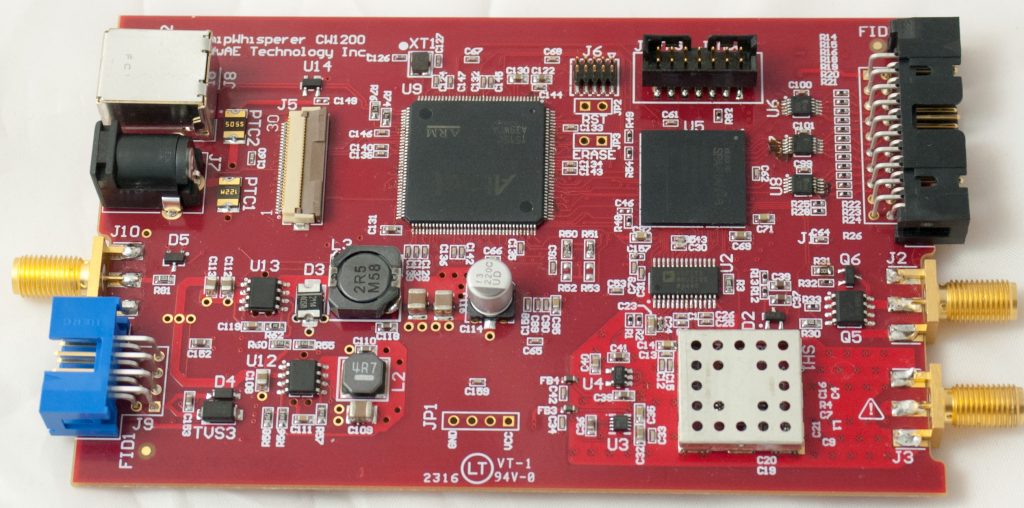

To give you an idea of what we’re working with, Figure 1 shows an example of the final PCB I designed and assembled. This uses a Spartan 6 LX45 FPGA with an Atmel SAM3U microcontroller for high-speed USB communications.